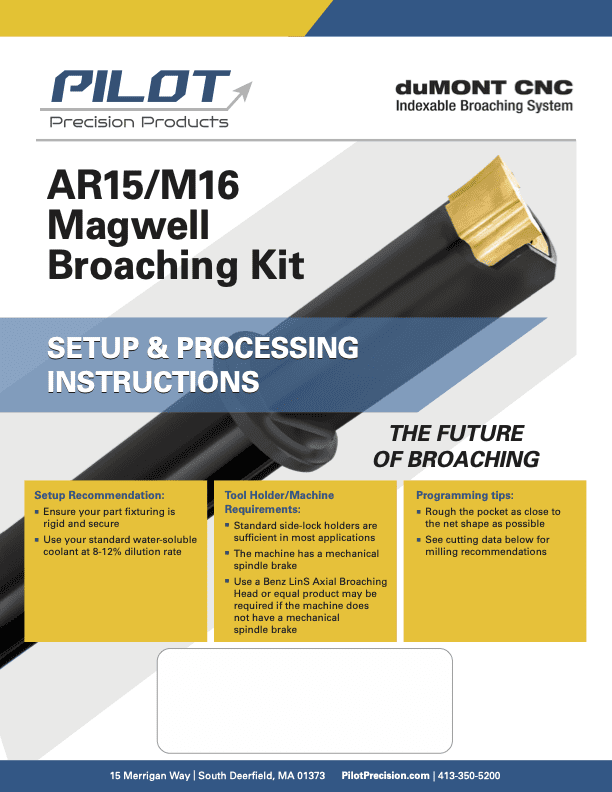

Indexable Broaching Systems

Indexable Broaching Systems Combine Flexibility & Rigidity to Deliver Superior Performance

With generations of experience delivering American-crafted precision broaching tools, our passion for developing new technologies that solve problems gives our Indexable Broaching Systems the ability to improve productivity, quality and consistency with the right broach in ways that stand the test of time.

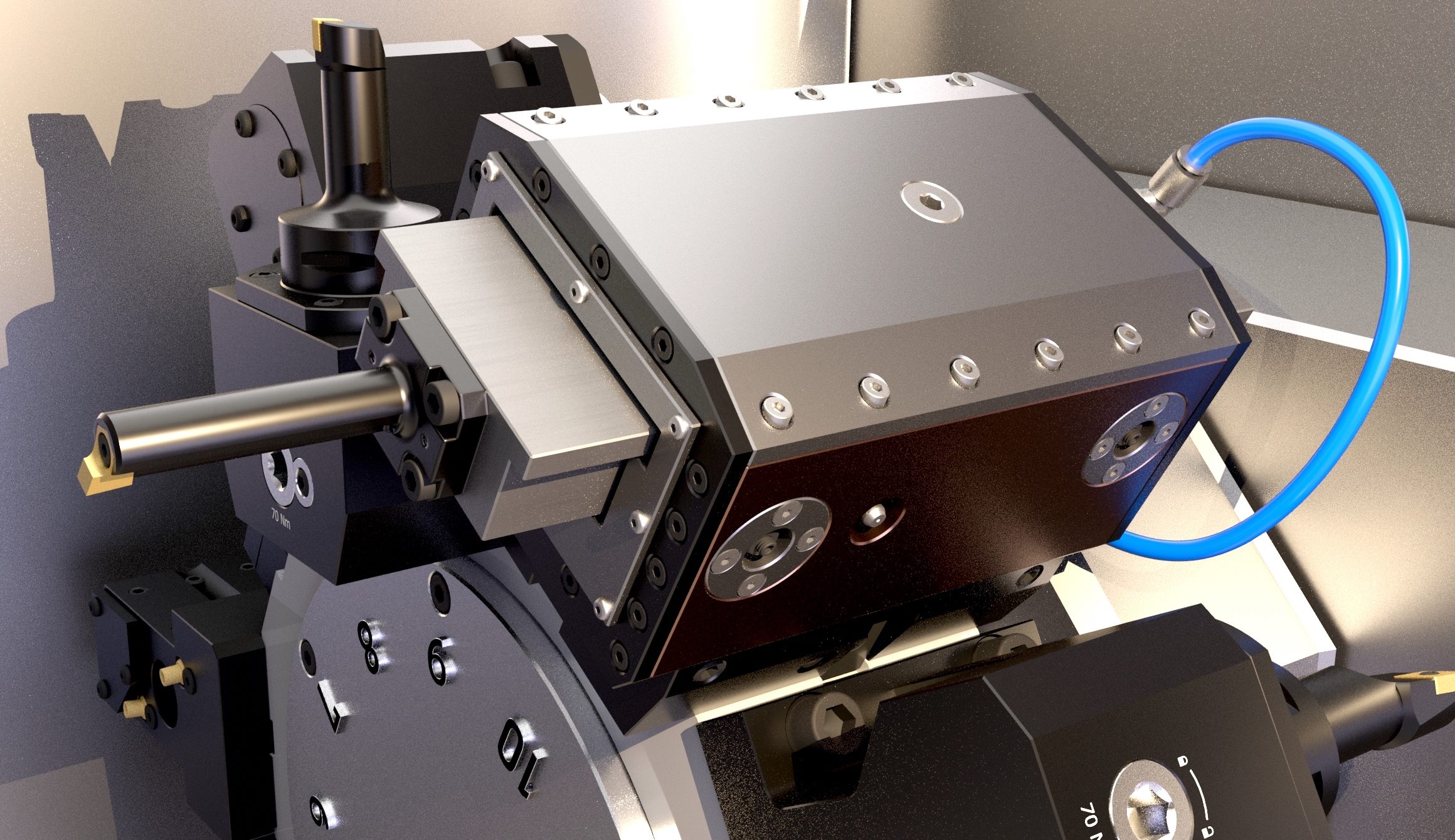

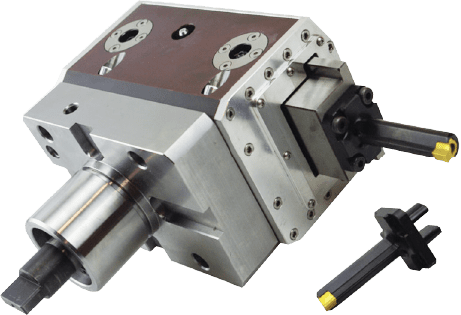

We’ve Teamed Up with Global CNC to Make Broaching Possible on Advanced Turning & Milling CNC Machines

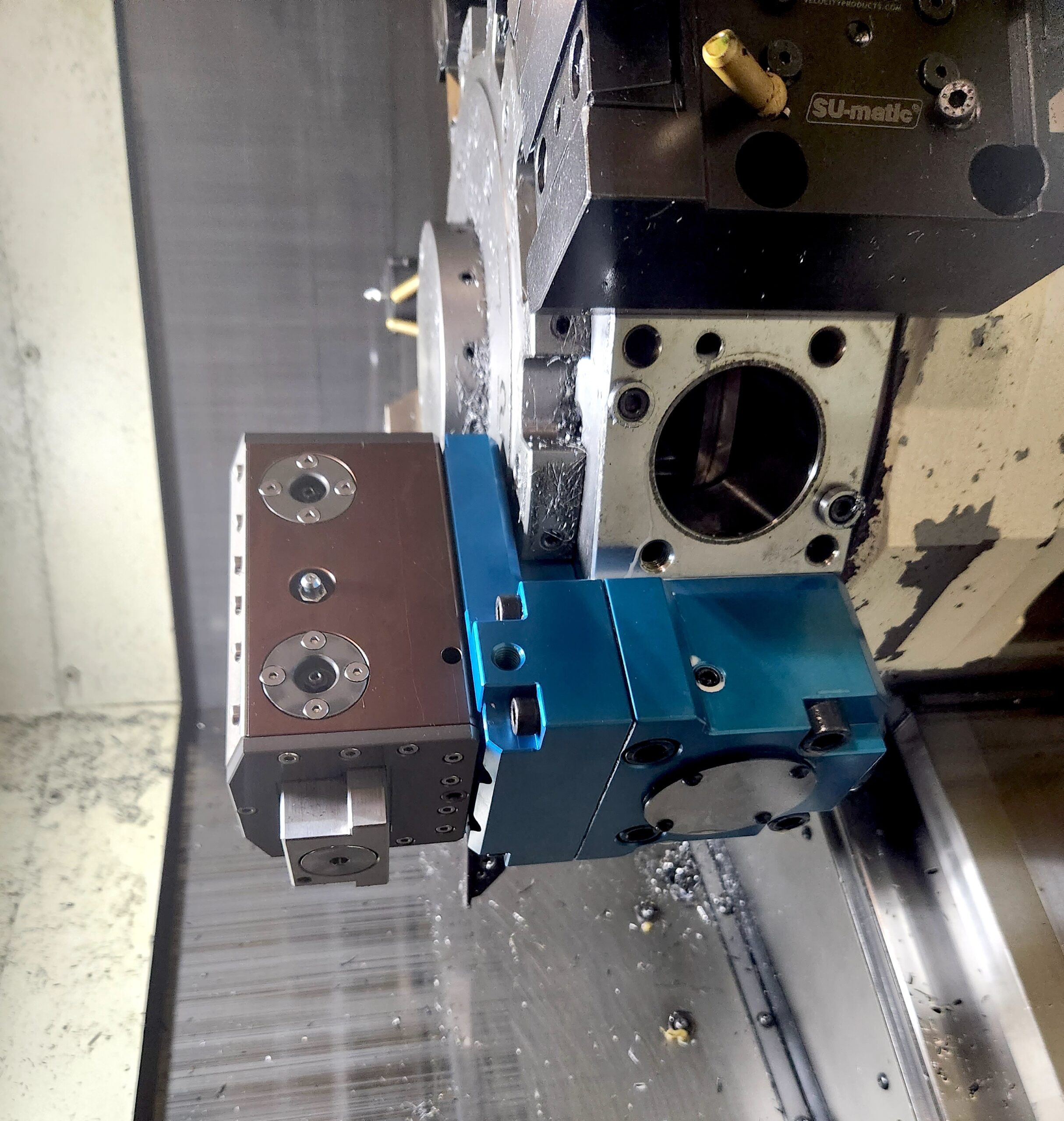

To help you get the most out of your machining centers, we’ve combined our duMONT CNC motorized slotters with the right-angle interfaces of Global CNC (GCNC), a leading manufacturer of static and driven tool holders. This collaboration allows you to increase the versatility of your machining centers and enhance productivity.

Whether you use a vertical or horizontal machining center manufactured by Okuma, Mazak, DMG Mori, or any other machine builder, our partnership with GCNC allows you to benefit from a unique combination of broaching expertise and knowledge of machine tool interfaces.

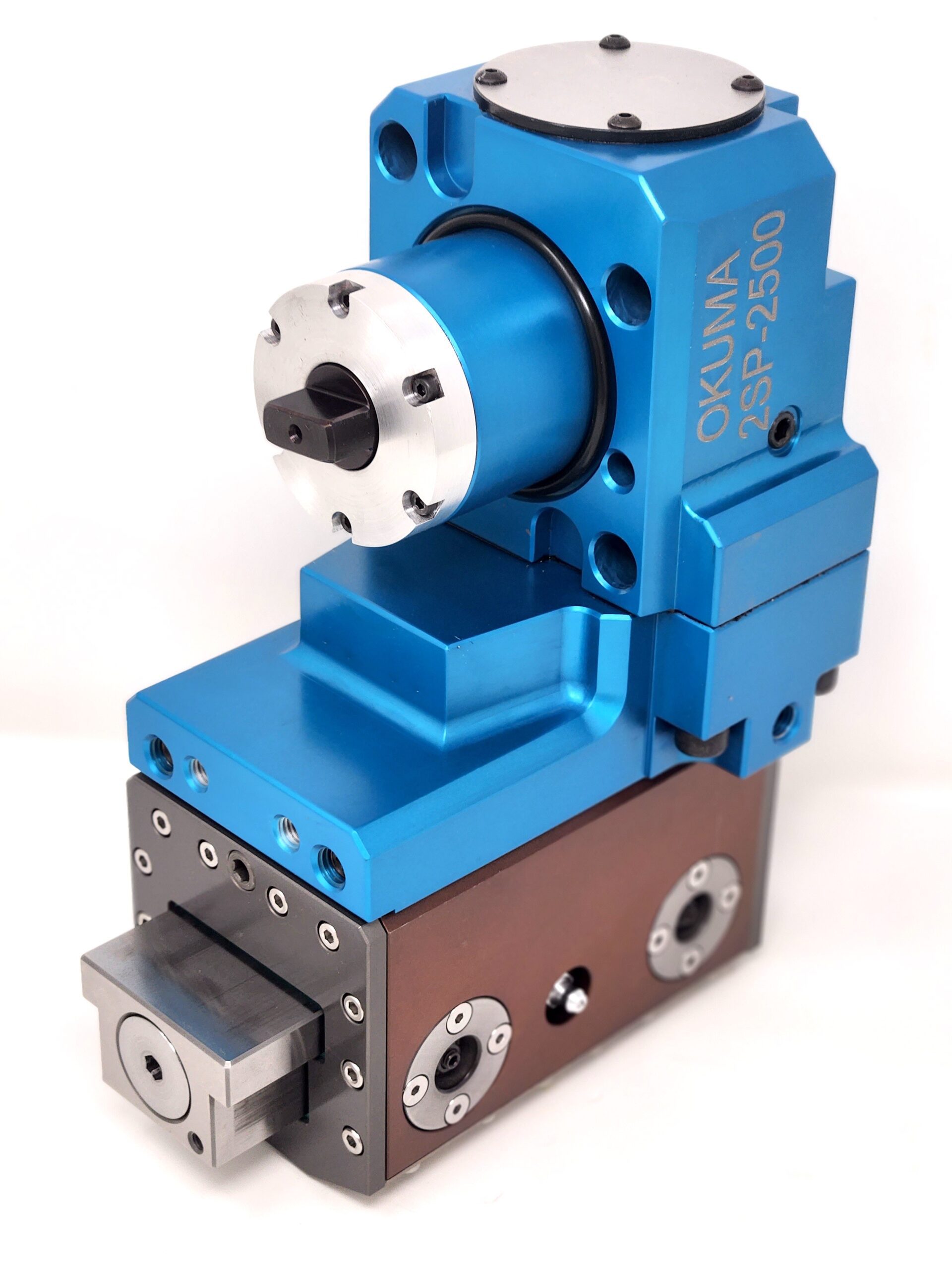

We recently worked with GCNC to develop a right-angle head (pictured) for an Okuma 2SP-2500 machine. The customer, who had asked several of our competitors for assistance before coming to us, needed clearance of the spindles to access the features to be broached efficiently, and with precision and stability. In short, we did what no one else could!

Passing the Test

Although GCNC received proposals from other manufacturers that wanted to partner with them, their testing showed that our duMONT CNC Motorized Slotters are a perfect fit for GCNC’s tool holders. That’s because our indexable broaching systems offer unique capabilities for ID/OD machining and simultaneous deburring of splines, slots, keyways, squares, hexagons, and custom shapes. To meet your challenges related to broaching and other machining operations…

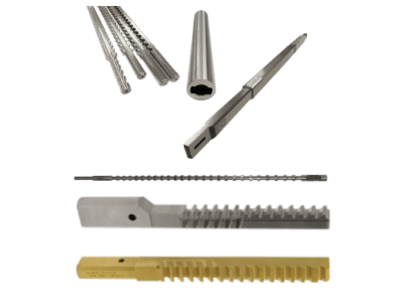

Our indexable broaching systems have unique capabilities for ID/OD machining and simultaneous deburring of:

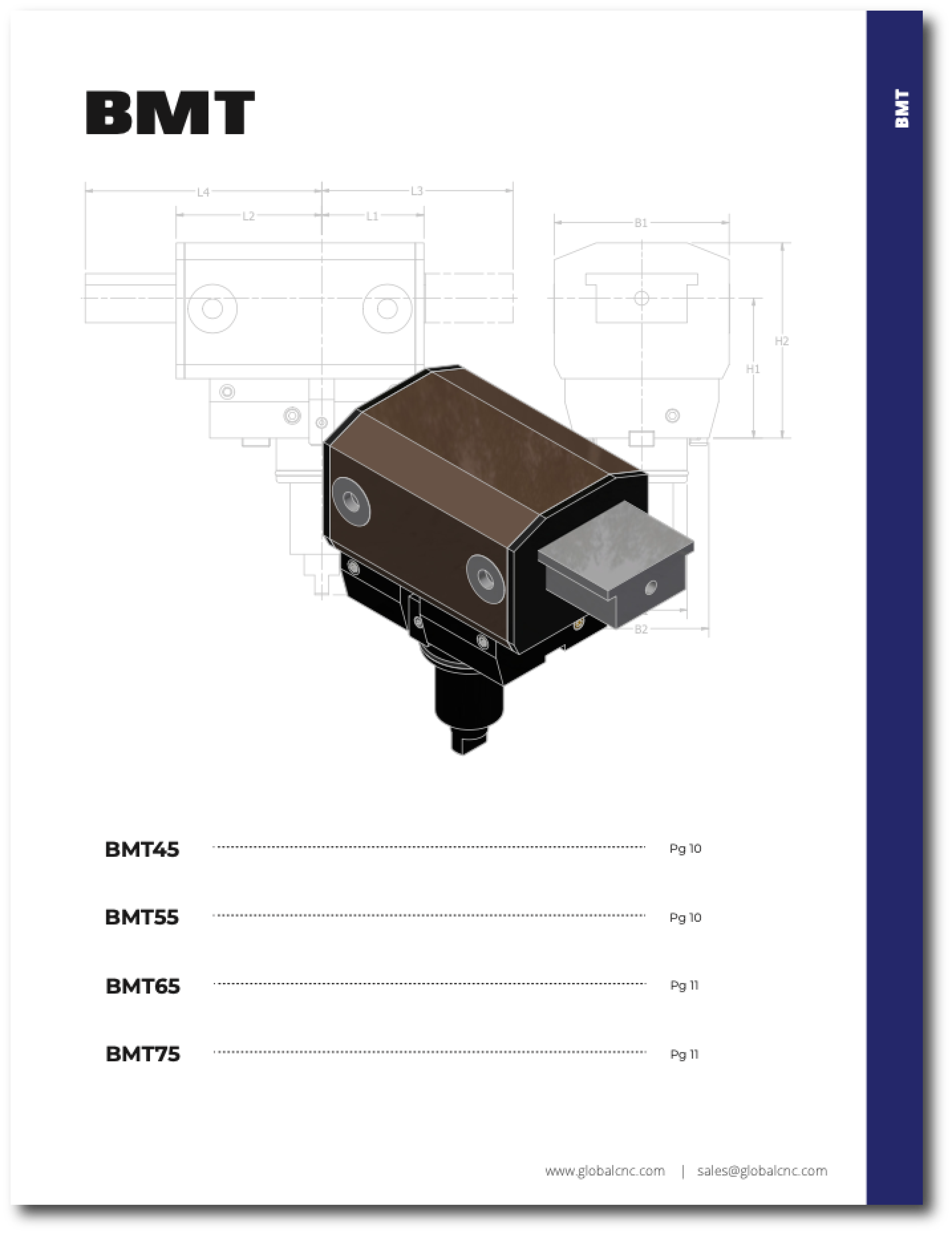

System Mounting

Easy Y- and X-Axis Adjustments

Broach up to 10x faster using our live tool attachment. Learn more about our CNC broaches offering exceptional accuracy and efficiency on CNC lathes and machining centers, as well as slotting and shaping machines…

NEW for Machine Tool Dealers

Include Our Tooling Concierge in Your 3-Point Partnership

Just as a hotel concierge recommends the best places to eat & shop, we welcome the opportunity to serve as your Tooling Concierge and recommend the best precision cutting tools for your and your customers’ applications.

Tooling certificates are available with any new machine purchased. By purchasing a certificate up front as part of your investment, you will be able to free up your tooling budget and equip your new machine.

As your Tooling Concierge, we use our expertise to understand your complex machining applications and recommend the right tooling. At Pilot, we also leverage our technical knowledge and business relationships to connect you with four of the world’s most respected brands of broaching tools, reamers, micro endmills & drills, and more.

SUPERIOR PRECISION, QUALITY, CONSISTENCY, AND PERFORMANCE.

Splines

Tools for Splined Profiles

The spline profile broach tool line was designed to make splined internal profiles. The choice of tool is determined by the minimum entry hole of the workpiece to be machined. In fact, we recommend purchasing a tool with a diameter (D2) as close to the value of said hole as possible. It is also possible to make special tools in various diameters and sizes based on specific customer needs.

Slots

Broaching and Slotting Inserts

The inserts designed to work exclusively with duMONT Tool Holders are a sintered steel alloy with a 13% cobalt content, heat treated to a 72 HRC hardness providing toughness and impact resistance. A TiN coating is applied to improve wear resistance and lubricity. All inserts are designed to allow several re-sharpenings. View the Engineering Section of our catalog below for process and Special Insert information and available applications – Keyways in Tapered Bore, Square, Hexagon and Involute Internal Gears. We can add custom corner radius per your requirement.

Keyways

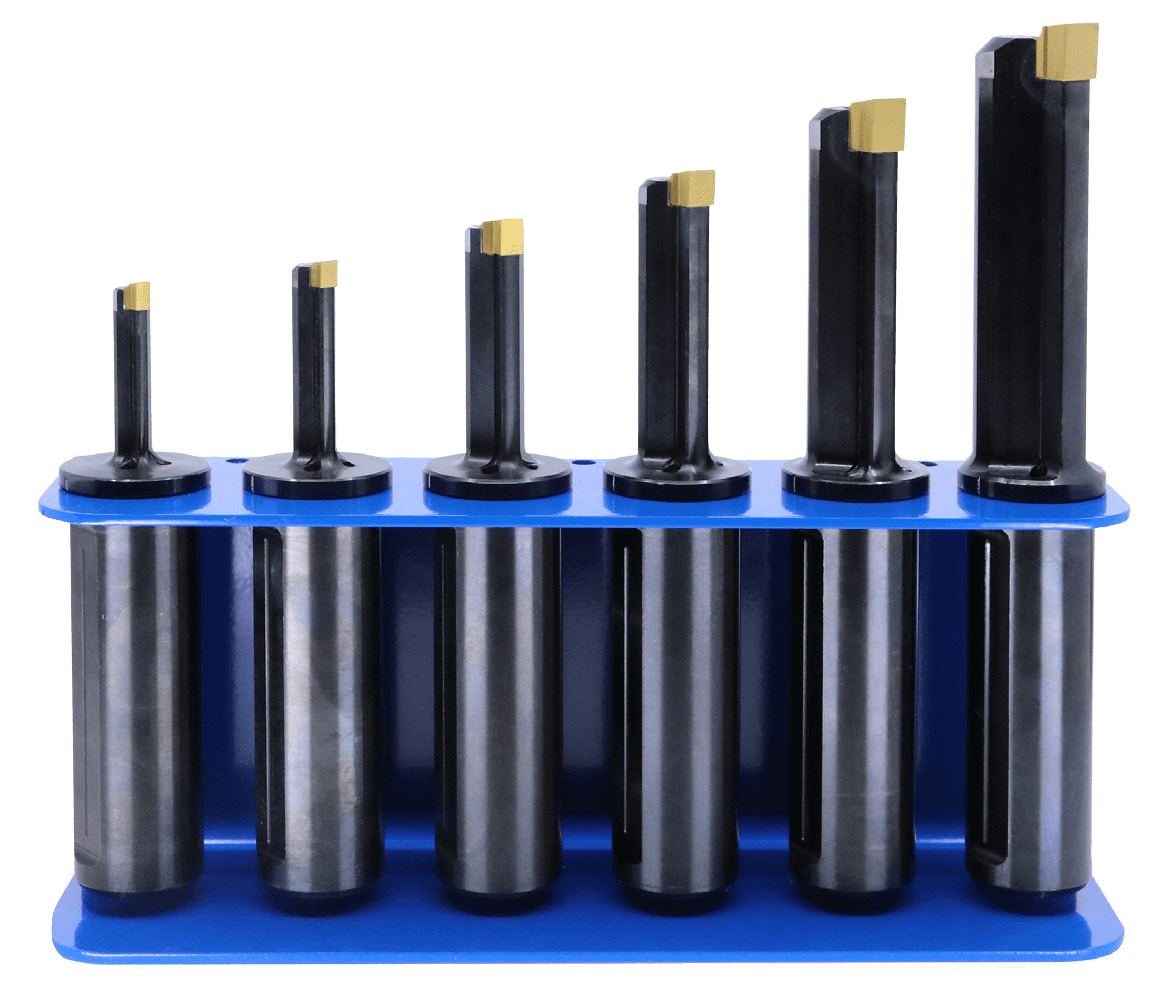

Stock Tool Holders for Inch and Metric Keyway and Slotting Inserts

The Tool Holders designed to work exclusively with duMONT Stock Keyway and Slotting Inserts are heat treated tool steel, hardened to 58/60 HRC at the Insert seat providing resistance to deformation and longer tool life. Most Tool Holders provide two 3.55mm holes for Thru Tool Coolant delivery promoting lubrication, cooling and chip flushing improving finish and tool performance. View the Engineering Section of our catalog below for additional process and Special Insert information and available applications – Keyways in Tapered Bore, Square, Hexagon and Involute Internal Gears.

Squares

Tools and Inserts for Square

Our series of duMONT tools was developed to execute internal squares. It offers the following advantages: absolute concentricity, the possibility of correcting the required measurement, machining speed and cost savings. Every insert size in this line is able to execute various square sizes, which makes using duMONT tools for squares very economical and convenient.

Hexagons

Tools and Inserts for Hexagon

The duMONT CNC Indexable Broaching System was developed to execute internal hexagons. It offers the following advantages: absolute concentricity, the possibility of correcting the required measurement, machining speed and cost savings. Every insert size in this line is able to execute various hexagonal sizes, which makes using duMONT tools for hexagons very economical and convenient.