Established Rotary, Index and Punch Broaches Made for all Alloys

The broach authority: With superior American craftsmanship combined with a passion for unmatched quality and consistency, Hassay Savage’s tooling delivers a distinctive competitive advantage.

In standard and specialized sizes and shapes, Hassay Savage’s portfolio covers:

For additional information about our hexagonal and square rotary punch broaches and Swiss style rotary punch broaches…

Customers also purchased…

As your Tooling Concierge, we use our expertise to understand your complex machining applications and recommend the right tooling such as Industrial Broaches, Rotary Broaches, Keyway Broaches, Custom Broaches, Indexable Broaching Systems, Rotary Broaches & Tooling for Swiss, High-Performance Round Cutting Tools and High-Precision Micro Drills. We also leverage our technical knowledge and business relationships to connect you with four of the world’s most respected brands of broaching tools, reamers, micro endmills & drills, and more.

RFQ

SUPERIOR PRECISION, QUALITY, CONSISTENCY, AND PERFORMANCE.

Custom / Index Broaches (Hex, Square, Hexalobe…)

Index Broaching can be performed on multiple machining applications. For instance, the CNC machining centers are the most common for Index Broaching: Lathes, Swiss Style Machines, and Vertical Machining Centers.

Hassay Savage Index Broaches provide longer production runs, superb surface finishes, and outstanding tool life in Stainless and Titanium. These broaches come in special sizes and special tolerances, and can be delivered in less than five days.

CNC Single Point Keyway Broaches

Broaching keyways on CNC machines today is as common as turning a part. Set-up is quick and our broaching keyways will eliminate part handling and improve your control. Save time and money with blind hole and thru hole CNC keyway broaching with standard tools that are off the shelf. Some of the advantages to the Single Point Keyway Broach is that you are able to complete the part on one machine, improve your process, and manage small lot production. This is the only way to keyway a blind hole.

Become more flexible with machining and use cost effective standard tooling, no brushing guide or hydraulic press or pull required. Our standard tooling comes with common shank diameters and the strength and rigidity in the set-up will allow for longer tool life. With the Single Point Keyway Broach, your keyway production will achieve excellent finishes and better accuracy. Specials are available with expedited delivery.

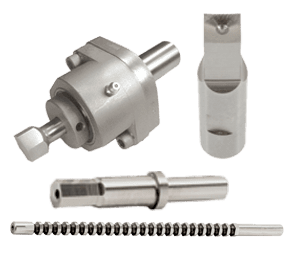

Hexagonal, Square and Punch Rotary Broaches: M-2 and MAX

Our HassayMAX hexagonal punch broaches, square punch broaches and adjustable punch broaches are manufactured from custom hardened alloys and are a specially formulated material that combines high hardness with exceptional abrasion resistance and toughness. They’re ideal for sockets where long tool life is required.

Hexagonal Rotary Punch Broaches can be used in a variety of machines and give you the ability to cut polygons in blind holes. The rotary punch broach can handle any type of CNC or manual turning, milling, drilling, or screw machine.

Our Square Rotary Punch Broach can be used with both screw machines and CNC machines.

Adjustable Punch Broaches can be used on any type of CNC, manual turning, milling or screw machine. Holders and broaches are sold separately and available from stock for immediate delivery. For optimal tool life in large production settings, these broaches should be used with Rotary Branch Holders.

Rotary Broaching Set-Up Plugs

We can supply you with custom turned diameters for your exact drill and bore size when repeatable set-ups are required for your job on a continuous basis, for both hex and square applications.

Swiss Style Rotary Punch Broaches

Our Swiss Style Rotary Punch Broaches offer consistent high-tolerance forms for long production runs. The broach has superb surface finishes as well as an outstanding tool life in both Stainless and Titanium. We can provide special sizes and/or special tolerances in less than five days.

Swiss Style Non-Adjustable Holders

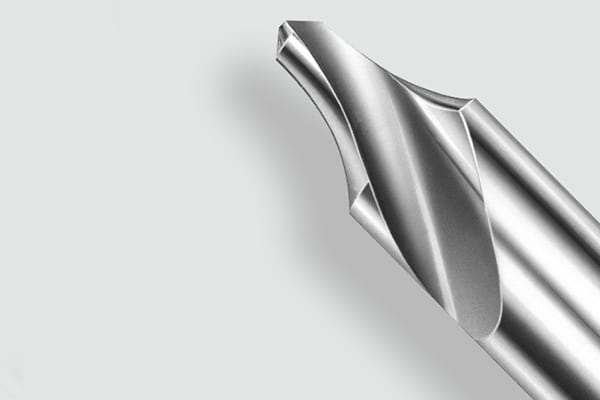

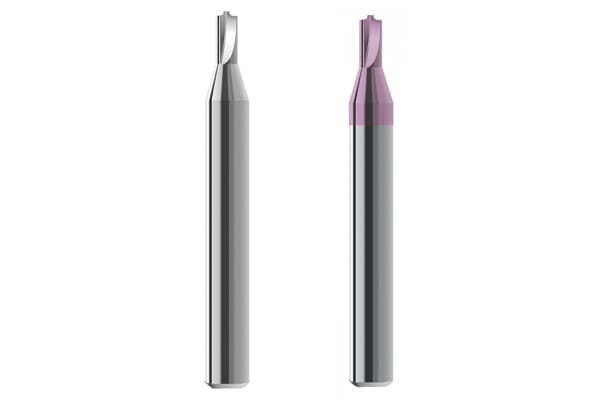

Magafor’s high performance micro-milling tool. Our Swiss Style Non-Adjustable Holders offer high performance results, and quality, consistent tool life that keeps machines running longer. No center indicating required and the Non-Adjustable Holder is self-centering. Its smaller head diameter eliminates interface on tool blocks. Longer shanks can be cut to proper length while a short head length allows for limited back work space.

Built-in wobble cutting feature 1° angle, our Non-Adjustable Holders are Swiss made for quality high-precision work and fit most Swiss type tool blocks and gang machines. They are heavy duty, with a bearing that takes 2,250 lbs. Pushing force, making it excellent for aerospace, medical part/bone screw, and dental part production applications with maintenance-free operation.